Authors

Rutger van der Zanden, Manager, Energy Transformation

Households and businesses are being hit hard by the energy crisis. Inflation is rising across many areas of life, and economic growth is slowing. The situation is particularly precarious in Europe, with the shortage of gas threatening energy cuts and the profitability of European business operations. Industrials are vulnerable to the energy crisis given the high energy intensity of their operations – primarily in the form of heat.

While there are no quick or easy resolutions for these problems, an accelerated energy transition is a key part of the solution. Locally sourced renewable energy provides an opportunity for businesses to reduce reliance on imported fossil fuels, limit further increases to their cost, and reduce exposure to volatile commodity prices, while at the same time making progress toward their climate targets.

Globally, industry is the largest user of natural gas, consuming (37%) of all gas, ahead of residential (30%) and commercial and public services (13%). Light industry, in particular, has an opportunity to replace meaningful quantities of natural gas with renewable heat this decade. Electrification will be key for this sector.

Why decarbonizing heat is an untapped opportunity

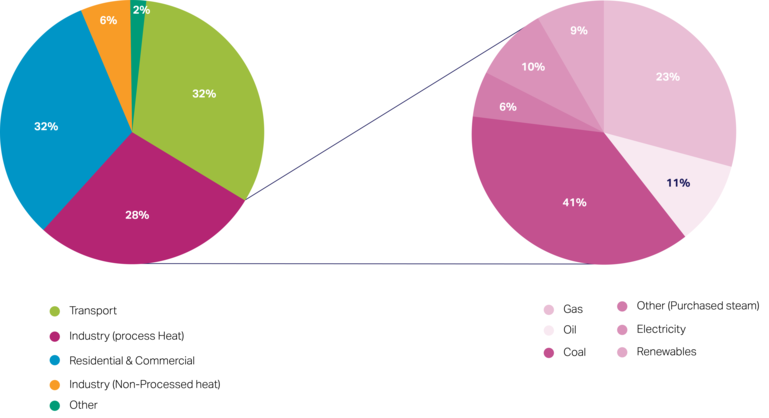

In total, industry accounts for 35% of global final energy consumption and 9.4 gigatonnes of CO2 annually. The vast majority of this energy is used as heat in industrial processes – both in heavy industry (such as cement and steel manufacturing) and in light industry (such as food or garment production).

Today, industrial heat is predominantly generated using fossil fuels. Only 9% of heat is generated from renewable sources, and this figure overstates the progress being made to deploy renewable heat given this use is concentrated in a few specific sectors – those that produce biomass waste and residues, such as pulp & paper, or food & tobacco. Most industrials have yet to introduce noticeable quantities of renewable heat into their operations.

In this article, “renewable heat” refers to heat generated with no or low carbon technologies such as renewable electricity, solar thermal, geothermal or sustainable bio-energy.

So why have we seen little progress in this area? And why is the global discourse on industrial heat seemingly centered around hard-to-abate sectors, despite some solutions for light industry being commercially available across many markets, and increasingly commercially viable?

Challenging market conditions and limited policy incentives are typically cited as the main reasons for the limited deployment of renewable heat solutions in industry. Generating heat with fossil fuels is relatively efficient (twice as efficient as generating electricity) and fossil fuels can be the most economical option, especially given many governments have yet to create the enabling environments that spurred on the wind and solar booms.

Limited deployment to date also means significant efficiency improvements and capital cost reductions have yet to materialize for growing renewable heat technologies such as high-temperature heat pumps and solar thermal. In contrast, solar PV systems have seen a fivefold cost reduction over the last 10 years, and lithium-iron battery prices have fallen by 19% for every doubling of capacity. Another consequence of limited deployment is a lack of corporate familiarity with novel technologies. In fact, the entire value chain has yet to optimize technical solutions for various use cases and link these with the most suitable business models and financing mechanisms.

Why the hard-to-abate sectors seemingly receive more focus than light industry is harder to explain. Attention has often been given to the largest industrial emitters, such as steel and cement and a lot of innovation, technology and policy work indeed needs to be done before we have commercially available solutions for these sectors. However, critical solutions for heavy industry like hydrogen and carbon capture and storage (CCS) also seem to have inherent advantages when it comes to mobilizing energy and industrial companies, the financial sector and governments: both can be applied across the majority of industry, and both are primarily deployed through huge capital projects. So how can we create similar levels of interest and engagement for the decarbonization of light industry?

Make no mistake, we at WBCSD very much encourage the crucial work that is ongoing to decarbonize heavy industry and scale these critical technology solutions. However, this attention should not come at the cost of focusing on – what is likely to be – the most efficient or economical lever for the majority of industries, direct electrification. Neither should it deter us from tackling light industry now, which by no means has an easy route to net zero ahead of it, but is, in fact, able to deliver a meaningful near-term contribution to wane the economy off fossil fuels and contribute to 2030 CO2 reduction goals – something neither hydrogen nor CCS can deliver, in the near-term that is.

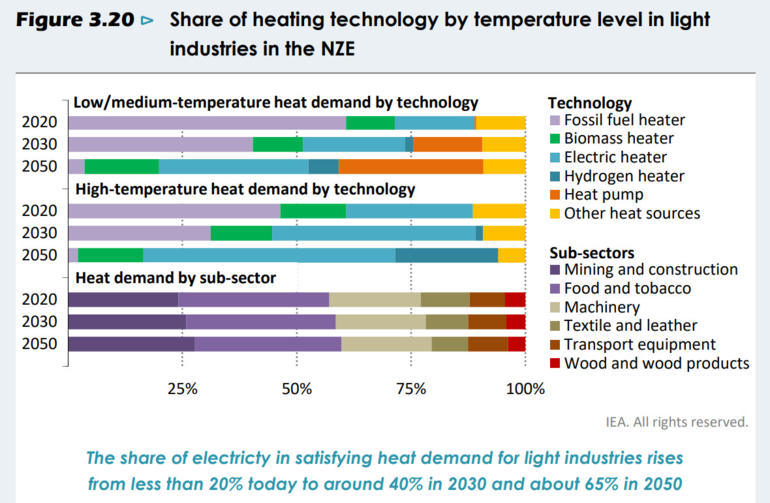

Source: IEA – Net Zero by 2050: A Roadmap for the Global Energy Sector

How to start decarbonizing light industry today

To accelerate the decarbonization of light industry, which jointly consumes close to half of all industrial heat, we must support dozens of smaller industrial sectors with different but not dissimilar heating requirements. We must mobilize fragmented value chains across various sustainable heat technologies while doubling down on efficiency and digitalization efforts. Adding in more complexity still, affordable mass electrification of industry will only be possible if the sector helps to resolve emerging grid constraints and captures the opportunity to balance variable generation from renewable power technologies like wind and solar.

Finally, we must find ways for the financial sector to help drive this industrial transformation. New business models such as Power Purchase Agreements (PPAs) have accelerated corporate renewable sourcing of electricity, and in turn, accelerated the clean energy transition of the power sector as a whole. For heat, which is characterized by decentralized generators and users without interconnected networks, the financial sector has yet to find ways to turn many smaller investments across numerous light industrial operations into a scalable opportunity.

WBCSD and its members have identified three business actions that will accelerate industrial companies’ ability to introduce renewable heat across their manufacturing portfolio:

1. Focus limited resources and capital on markets that are likely to provide an appealing business case for renewable heat solutions

The costs of natural gas or the presence of policy incentives will have a big impact on the commercial viability of renewable heat. The relative cost of power in comparison to gas, and the national power grids’ ability to incorporate additional electrical loads, will, in turn, influence to what extent electrification is feasible. Knowing where market, policy and climatic conditions are conducive to renewable heat investments ensures early efforts yield results.

WBCSD’s joint publication with BloombergNEF on Hot Spots for Renewable Heat highlights the market conditions relevant to clean heat investment across the G20, as well as the particular conditions relevant for key technologies from solar thermal and geothermal to bioenergy and direct electrification. Big European markets, as well as China and South Korea, are good places to start.

2. Leverage financial instruments such as Heat-as-a-Service (HaaS) to overcome key barriers that companies regularly encounter with renewable heat solutions

Many companies have faced financial barriers to the implementation of renewable heat due to relatively high capital expenditure requirements and sub-par returns on investment. Companies are also much more likely to want to spend available capital on core business, as opposed to cost and carbon-saving initiatives.

Heat-as-a-Service (HaaS), a growing business model not entirely dissimilar to Power Purchase Agreements, could provide a solution. HaaS overcomes financial barriers by involving a third party that invests in a low-carbon asset, guarantees its operational performance, and sells the energy generated through a long-term offtake agreement. Apart from carbon and operational cost savings, HaaS can provide strategic corporate benefits, provided sustainability, operational, finance and procurement professionals work together effectively.

3. Understand medium and long-term market trends driving electrification and approaches that companies can take today to make industrial heat pumps a commercially attractive proposition

The renewable heat technology widely expected to play the largest role in decarbonizing light industry is electrification (i.e., making heat with electricity rather than fossil fuels), and heat pumps are expected to play a particularly important role given it is the only technology with efficiencies greater than 100% (in that more energy can come out than you put in).

Introducing (steam-generating) heat pumps that can displace gas-fired boilers in manufacturing operations is, however, not straightforward. To drive uptake of industrial heat pumps, corporates can take various approaches to maximize returns, including coupling heating and cooling loads – within and beyond site boundaries – and play the power market to minimize electricity costs and leverage new revenue streams associated with grid flexibility services.

It can be easy to feel overwhelmed in the face of the current energy crisis and the complexity of the renewable heat environment. Silver bullets do not exist in this space. But bright spots do exist, and companies can develop solutions that marry carbon and operational cost savings with strategic targets to reduce economic, policy and geopolitical risks.

Could the global energy crisis be a historic turning point for the clean energy transition? If light industrial companies can seize the moment and leverage existing solutions to start decarbonizing their heat, they can make a significant dent in global emissions and decrease society’s reliance on imported and volatile fossil fuels. By paving the way for sustainable heat, business can future-proof their own operations and become true leaders in building a net-zero, nature-positive, and more equitable future.

If you want to learn more about WBCSD’s work on industrial heat, please contact Rutger van der Zanden, Manager Energy Transformation.

WBCSD news articles and insights may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Privacy Policy. All Content must be featured with due credits.