The issue / context

Although the availability of fresh water is a global issue, water constraints tend to affect people and the environment at the local or regional level. Therefore the way Shell (QGC’s parent company) manages its use of fresh water depends on the local situation, and requires tailored local or regional solutions. This includes looking for ways to reuse and recycle this valuable resource.

At our QGC project in Australia, we have invested in water treatment facilities to turn produced water into a resource that can be used by the local community.

QGC produces Liquefied Natural Gas (LNG) from natural gas in the drought-prone region of the Surat Basin in Queensland. Water is produced as a natural by-product during the extraction of gas, but it is often brackish, and unfit to drink or use on crops.

Objective and project overview

The Queensland Government developed a hierarchy of potential uses ranging from benefial use to other environmentally acceptable methods for water produced during natural gas extraction. Beneficial re-use1 was chosen by QGC due to the ongoing benefits to the communities in which the company operates. However, for beneficial use to be effective the water needed to be treated to a standard fit for irrigation.

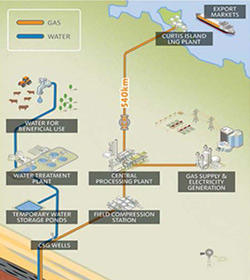

QGC manages the volumes of water produced from the well‐sites via an extensive network of pipelines, pump stations and produced water storage ponds that transfer the water to one of two centralized water treatment facilities (Figure 1).

The two water treatment plants include brine concentrators to reduce the waste stream to only 3% of input and allowing re-use of 97% of the produced water. The high-quality water is suitable for use by local farmers and irrigators, as well as industry and town water suppliers.

Following treatment, water is delivered to two large water supply schemes managed by a State water service provider.

The plants have been operational since 2014 and their combined average treated water output in 2016 was 65 mega litres a day – or about 25 Olympic-sized swimming pools.

The business case

QGC produces natural gas from unconventional coal reservoirs. Natural gas in coal seams is held in place by the pressure of groundwater. Therefore, for gas to flow to surface, groundwater needs to be extracted to relieve this pressure. Under Queensland legislation, gas companies are permitted to extract groundwater during gas production. In turn this requires the management of large quantities of groundwater during the early phases of the project, declining towards the end of field life.

Therefore, water management is a large proportion of the overall project capital and operating costs. QGC’s beneficial use options allow the maximization of benefit to the community and help defray some of the operating costs. For QGC it means there are guaranteed outlets for the produced water and a reduction in storage and discharge costs. For the local farmers and irrigators, it means access to a secure supply of clean water in an area naturally prone to drought. And for the environment, it reduces pressure to irrigate from river systems meaning the local ecosystems are protected.

Decision-making process

The water treatment system went through the same decision-making process as other major elements of the project. This pathway is best summarized as Identify-Assess-Select-Define-Operate where selected options are taken through a number of formal stage gates informed by the required degree of technical, non-technical and economic analysis and risk assessment at each stage2.

At the early stages of the project there were three main options for water discharge management, in accordance with relevant Queensland legislation. Those were: irrigation to dedicated plantations; injection into aquifers; and beneficial use. Overall, the reviews indicated that technical risk was minimized and benefits to community were maximized by the beneficial use option.

Project details & finances

Water is collected from up to 3000 gas production wells and delivered to regional storage ponds via a gathering network. Flows are then directed to one of two water treatment plants, each of 100Ml/d design capacity.

QGC manages the produced water volumes as two discrete systems which are aligned with the Southern, Central and Northern Development Areas. Water produced from the Southern and Central Development Areas is treated at the Kenya Water Treatment Plant (KWTP). Water produced from the Northern Development Area is treated at the Northern Water Treatment Plant (NWTP). Each plant delivers water to one of two beneficial use schemes.

The design of the water treatment plants is based on the three treatment processes of ultra‐filtration (UF), ion exchange (IX) and reverse osmosis (RO). These processes achieve 90% recovery of produced water and are designed to accommodate the naturally varying water quality whilst meeting the strict treated water quality standards required to facilitate beneficial use via the outlets. The Brine Concentrators (BCs) recover a further 7% as distillate, leaving 3% of the volume remaining as concentrated brine.

Water outlet security is critical to ensuring water production does not constrain gas production. To facilitate this, QGC has entered a long-term arrangement with SunWater, a Queensland Government-owned Corporation, to facilitate beneficial use of treated water by customers.

QGC’s water treatment facilities are strategically located near the two beneficial use schemes, which are currently operational. QGC is responsible for treating the water to the required standard with SunWater pumping the treated water via purpose built pipelines to distribute treated water to customers for beneficial use.

The Dawson Valley Beneficial use Scheme takes treated water from the NWTP along a 120-km pipeline from Woleebee Creek to Glebe Weir on the Dawson River. The water is distributed to customers along the pipeline route and within the Dawson Valley Water Supply Scheme.

In a similar manner, the Chinchilla Beneficial Use Scheme takes treated water from the KWTP along a 20-km pipeline to the Chinchilla Weir on the Condamine River. The water is distributed to customers along the pipeline route and within the Chinchilla Weir Water Supply Scheme QGC pays for and operates the infrastructure required to gather and treat the water we produce. This enables us to provide water for beneficial use on farms, by industry and to supplement local town water supplies. QGC has invested more than AUD2 billion on water-related treatment infrastructure, research, modelling, monitoring and management.

Project results

The project provides water that would otherwise not be available to local farmers and towns. It provides farmers and irrigators the ability to plant winter crops in the region, knowing there will be water available for irrigation when rainfall and river water allocations are limited. Moreover, providing water helps take pressure off environmental flows by supplementing the region’s water supply schemes. QGC has an assured water disposal system which optimizes gas production and enhances its License to Operate.

QGC’s water-recycling efforts were recognized by the 2016 Global Water Awards which named it Industrial Water Project of the Year.

Lessons learned

Some key lessons learned have been:

- A modular design has successfully allowed downscaling of water treatment in response to changing production priorities. Flexibility is also available to ramp up where necessary.

- Scheme management - recognizing that water management is not QGC’s core business, QGC has successfully outsourced management of the water treatment plants to a water service company on a 25-year operations contract. Similarly, the construction of the discharge lines and management of the water supply to landholder is successfully carried out via a local water service provider.

- A system whereby irrigators apply for water volumes and are obligated to take that nomination provides security of discharge and minimizes storage costs.

Future implementation and next steps

The plants are designed as modular systems. The flow rate of groundwater flow will decline as the rate of gas increases and units are taken off line to meet the reduced demand. Alternatively, as additional gas reserves are developed then the plants can be scaled up to manage the additional volumes. Measures are underway to identify how the plants can be utilized to assist local communities and commercial operations with additional water management capacity and provide a legacy going forward for the Surat Basin.

Download case study

References

- http://www.shell.com/sustainability/environment/water/reusing-and-recycling-water.html

- http://www.shell.com.au/about-us/projects-and-locations/qgc.html

Project detailsCompany: QGC Pty Limited Country: Australia Business sector: Oil and Gas Industry Author(s): Alfio Mianzan, Environment Manager Water and Green Infrastructure, Shell Global Solutions Contact information: Albert J.H. Janssen, Environment Manager, Water albert.j.h.janssen@shell.com Marjet Visser, External Relations Adviser, marjet.visser@shell.com |